Putting sandwich panels to the test

Being a crucial part of the combined solution delivered by Hilti, Paroc Panel System and Rf-Technologies, a large 3 by 2m setup of multiple CU2 fire dampers in Paroc sandwich panels has been tested at the Warringtonfire test lab in Ghent.

Per EN1366-2, the European test standard for fire dampers, a CE certification is only valid for the specific wall material and related sealant and installation method in which it has been tested.

Sandwich panels, still being fairly new in the market, are not considered as a standard wall type in the test standard, resulting in the need for engineering judgments and acceptance of such by fire safety authorities. Some large data center projects have opted for sandwich panels as compartment structures, capitalizing on the benefits of shorter construction cycles thanks to sandwich panels wall systems. The light, prefabricated panels can be easily transported to site and quickly erected, allowing other trades to begin their work immediately. In facilities such as data centers where every additional day of uptime counts, these fast-track construction methods are helping improve and accelerate the return on their construction investment.

Unfortunately, the current situation on standards for fire testing penetration seals in sandwich panels has frustrated many designers looking for solutions in these types of walls. Firestop manufacturers cannot compare results across panel types or manufacturers, making widespread testing cost prohibitive and leading to an industry-wide lack of tested systems in these wall construction types.

To overcome the issue with using sandwich panels in a fire safety context, a 3 party collaboration has been setup by Hilti, Paroc Panel System and Rf-Technologies. This partnership aims to obtain a market approved and CE certified ‘system’ solution, comprising sandwich panels (Paroc Panel System), penetration fire stop (Hilti) and fire dampers (Rf-Technologies).

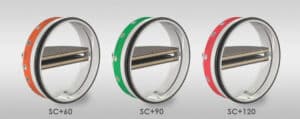

New classifications make Rf-t’s SC+ Butterfly Valves unique in the market