MG-U. A new U/U fire-resistant collar designed for cost-efficiency

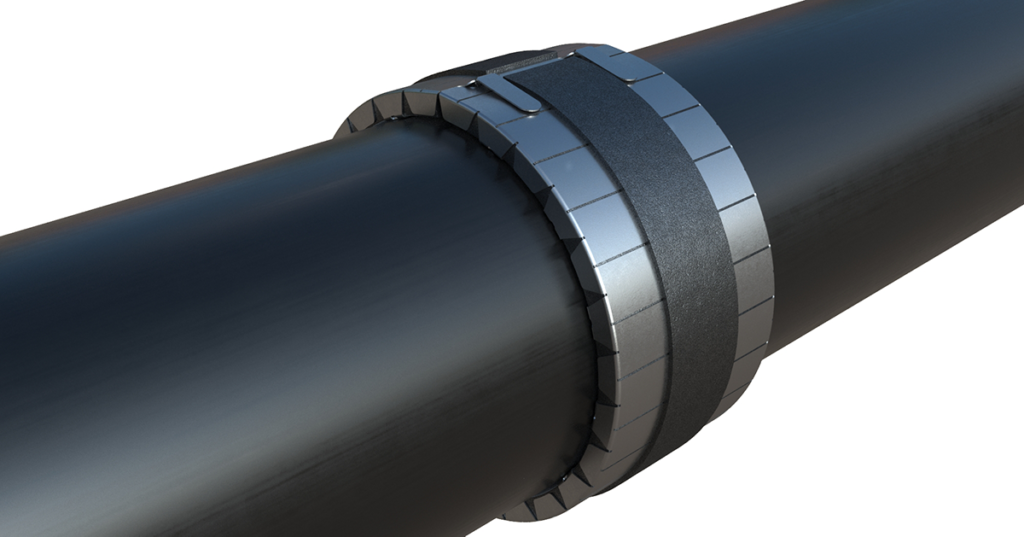

Rf-Technologies recently launched the new MG-U fire collar with uncapped/uncapped (U/U) classification and a unique design offering many advantages for installers.

Like all fire protection products, collars are subjected to strict testing. The latest European test standards specify that only collars tested according to EN 1366-3 can be approved for use.

For the correct application of fire collars, there is an important distinction between capped and uncapped solutions. The newest MG-U fire collar is classified as U/U and can therefore be used with all types and diameters of plastic pipe (PVC, PP, PE, ABS and SAN+PPVC).

Why are fire-resistant collars used?

Plastic pipes burn away quickly, allowing fire to spread through fire compartment walls. That is why fire-resistant collars must be installed in every fire compartment wall or floor: in the event of fire, the openings are filled by the tumescent material to maintain the integrity of the fire compartment.

Advantages of the MG-U flush-mount collar

A flush-mount collar (in a floor or wall) has several advantages over a surface-mount collar: only one has to be installed in a wall, and access on a single side is sufficient. With penetration into a shaft, for example, an MG-U collar can be installed easily even if there is no physical access to the shaft. There is also no loss of space at the penetration, so a bend or socket fitting can be installed against the wall or floor. This improves the arrangement of the whole assembly.

A further advantage of the MG-U collar is that it can be sealed with polyurethane foam. Because the foam swells, the sealant only needs to be applied from one side. A single collar in the wall instead of one on each side also saves considerable expense and time.

Sealing with polyurethane foam is a unique and patented solution.

What does uncapped/uncapped (U/U) mean? Why is there a difference between vented and unvented pipes?

Since 2017, only products tested according to European standard EN 1366-3 are allowed to be marketed and used. The European test standard distinguishes between capped and uncapped. In the uncapped case, the plastic pipe must remain open during an oven test, so it is not closed with a plug. This means the hot gases can pass through the pipe, making it significantly more difficult to meet the criteria for fire integrity (E) and thermal insulation (I) in this case. A fire breakthrough could therefore occur much faster. Uncapped tests impose far tighter requirements on fire-resistant collars, which in practice means that the collars must respond much faster to satisfy the compartment integrity requirements.

Uncapped tests are based on the idea that hot gases may be able to spread through pipes because the pipes are not completely filled with liquid, but rather are at least partly vented. Vented pipes are often used in construction for rainwater drainage and downpipes, as vented drain lines (wastewater), etc. Water supply pipes and hot water pipes are typical examples of unvented pipes. A fire-resistant collar that is tested uncapped in the oven fulfills the most stringent requirements and, in line with the specifications of European test standard EN 1366-3, also fulfills the requirements for capped solutions (uncapped/capped, capped/uncapped and capped/capped).

In other words, a fire collar with U/U classification also effectively has U/C, C/U and C/C classification. Whether the pipe is vented or unvented, with a U/U classification such as with the MG-U, you are always on the safe side.

The MG-U fire collar has U/U classification, making it suitable for use with all types and diameters of plastic pipe

Sealing MG-U collars with polyurethane foam makes things a lot easier for installers

If the collar pinches the plastic pipe closed in time to maintain the integrity of the compartment but the opening between the pipe and the wall or floor is not correctly constructed, fire and smoke can also spread to the next compartment through this opening. Correct and effective sealing is therefore very important. Rf-Technologies is constantly looking for innovative solutions to make sealing as easy and economical as possible for installers. The MG-U collar is fitted around the pipe and pushed into the wall, and then the space between the wall and the MG-U collar and pipe is sealed with standard polyurethane foam.

Polyurethane foam has the advantages of being inexpensive, quick to apply, and not needing any finishing afterwards. Sealing with polyurethane foam is a unique and patented solution. In the event of a fire, the standard (flammable) polyurethane will burn away completely and be replaced by a special tumescent material on the outside of the MG-U collar. This means that the MG-U fire collar in the wall or floor is actively effective both inward and outward, and the integrity of the compartment is protected.

New classifications make Rf-t’s SC+ Butterfly Valves unique in the market